More and more companies are focusing on the energy efficiency of their products. And this is no less important in the lift industry. Which is why, at ILS, we use new technologies as gearless motor, design improvements and optimisations that reduce daily energy use and polluting waste.

As it happens, many of these features are present in our new ION lift. In fact, the entire cab lighting system features LED technology, and there is a “stand-by” mode for night-time hours and extended periods when the lift is not being used. As part of this commitment to energy efficiency, there is a lot of talk about gearless technology as a major performance improvement. But what exactly is it?

It’s a machine without a reduction gear, which cuts down on losses due to friction. It also features a variable-frequency drive for easier control. In addition to providing for excellent levelling, this technology improves ride comfort and reduces noise levels. Let’s take a look at its benefits one by one.

What are the advantages of gearless motor for lifts?

Enhanced safety

Its braking system acts directly on the axle for maximum safety. In addition, gearless technology greatly improves ride comfort and prevents a sudden stop upon reaching the desired floor.

Low noise

Thanks to the low RPMs at which the motor turns, and to its design, this machine reduces the main sources of noise and vibrations typical of a lift. It does not require forced ventilation and it features a silent braking system. As a result, the residents on the top floor, who are most exposed to these noise and vibration problems, tend to be the most appreciative when this machine is installed.

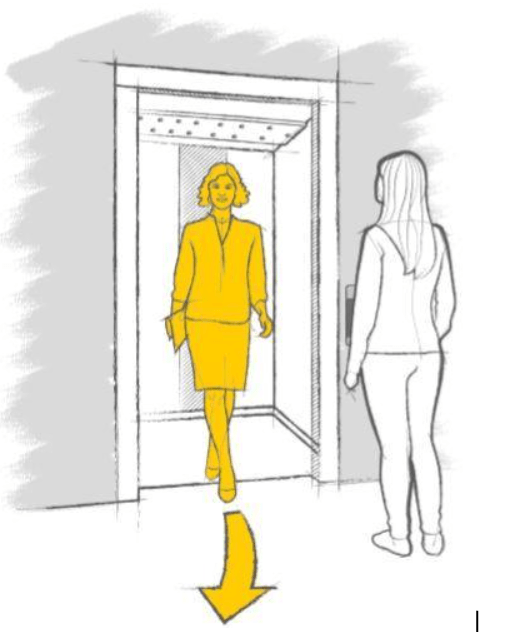

Perfect levelling between the cab and floor

This system offers more accurate cab-floor levelling, a crucial feature for accessibility. Increased stopping accuracy (as shown in the image) allows passengers to get in and out of the lift easily, comfortably and safely.

Space optimisation

Since there is no need for a machine room, gearless technology is ideal for buildings with little space available.

Higher loads

Gearless motors allow for higher loads than geared variants. They are therefore ideal for use in a freight elevator or to transport large numbers of people (such as in a hospital or factory).

Correct speed

Gearless drives usually have other electronic components to regulate the speed of the lift, such that the lift builds up speed gradually when it starts to move and decelerates just as smoothly when it comes to a stop. This avoids sudden starts and stops, which have a negative impact on ride comfort and on cab-floor levelling.

Lower electricity consumption and more durability

Thanks to not using a speed reducer, energy consumption with gearless technology is much lower in electric lifts than in lifts with traditional machines. This means lower electricity bills. Moreover, because they experience less wear and tear, these motors do not require constant repairs and they last longer.

Environmental protection

These machines are more environmentally friendly, since they don’t use any polluting lubricating oils.

As we have shown, installing this technology in a lift yields a significant improvement in user comfort. So if your lift has a conventional motor and you want to replace it with a gearless motor, contact us for more information. At ILS, we’re happy to help.

Basic information on data protection: In accordance with the GDPR and the LOPDGDD, FAIN ASCENSORES S.A. will process the provided data in order to contact you with the information you need. For more information about the processing of your data and to exercise your rights, please visit our privacy policy