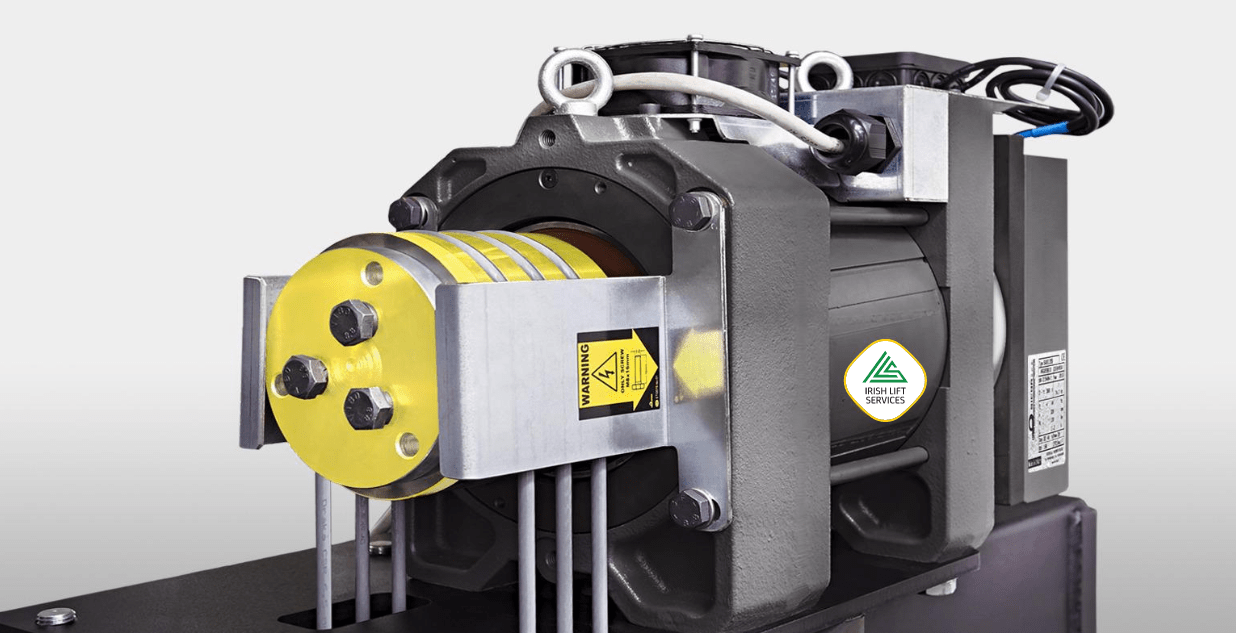

The lift power unit, known worldwide as ‘the machine’, is considered the heart of an installation.

It is located in the machine room next to the control panel and normally consists of a motor coupled to a speed reducer and on whose shaft is the traction pulley, which is responsible for pulling the cables that support the cabin and generate the movement.

Its useful life is limited and after a few years it is essential to change it. At this point, it is necessary to put it in the hands of a professional and solvent company.

You should also be aware that when replacing the power train, the cables must also be replaced. In fact, these replacements are usually quoted together. Replacing them at the same time is also a way of protecting the machine’s pulleys.

Why renew the lift power unit?

When a mechanical element is worn out and repairs do not guarantee long-lasting performance, a decision must be made to replace it with a new one.

In addition, the new tractor units guarantee better ride comfort, more precise stopping accuracy and significant energy savings.

The most efficient are gearless. They are somewhat more expensive because they require a control unit equipped with a frequency converter, but this initial investment is more than compensated for, as they can reduce energy consumption by 50% in this item.

In fact, the new regulations that are expected to be published in 2024 require the installation of gearless, oil-free, gearless traction units, as these are the only ones that guarantee a stopping accuracy of less than 1 centimetre in all operating conditions.

In other words: regardless of the number of people in the cabin, the distance between the floor of the lift cabin and the floor of the landing will always be less than one centimetre. This not only prevents tripping; it also facilitates access to the cabin for wheelchairs or pushchairs.

What other changes do we make when modernising a lift?

A modernisation is not only limited to an aesthetic issue, but goes one step further, as it seeks to technologically improve the lift by making it more modern, comfortable, safe and efficient.

It should be borne in mind that the lift is still a machine and that its components deteriorate progressively through use and the passage of time.

Apart from the traction unit, there are other parts of the lift that also need to be modernised over time. Some examples are:

The Controller

It is the ‘brain’ of the lift. It is responsible, by communicating with the traction unit, for processing the orders given by the users when pressing the call buttons and, in a logical manner, ordering the movement of the cabin to the requested floors. It also controls the speed of the movement, the approach to the floors and automatically stops the lift in the event of a failure in one of the safety components.

The cabin

It is one of the components that we also modified, being the one that is most visible when we get into the lift. We renovate the lighting by replacing the old fluorescent lights with LED lights to save on the community’s electricity bill. It is also possible to modify (and even personalise) the button panel, the mirror, the ceiling, the floor, the handrails, etc. Another part that the old machines did not have was the cabin telephone, but its installation is now mandatory to ensure two-way communication with the Customer Service Centre in the event of entrapment or any kind of unforeseen event.

Landing or landing doors

They are subject to a lot of wear and tear due to continuous use. For this reason, they must be replaced when deterioration is observed. It is also advisable to replace manually opening doors with wider automatic doors to improve accessibility and facilitate the use of the lift by people with reduced mobility.

Landing accesses

Landing accesses are changed to ensure or improve accessibility.

In short, if you are considering changing the traction unit or any other modernisation of your lift, remember that this is not an expense but rather an investment. It is also a way to increase the safety and availability of the lift.

Modernisations improve the reliability, quality and speed of lift travel, while increasing energy efficiency, correcting levelling errors at landings and minimising maintenance visits.

And best of all: A modern lift increases the value of your property!

If you are looking for a serious, solvent company with a long track record to help you with your next modernisation or the change of your lift power unit, trust us. Find out which of our branches is closest to you! Contact us and ask for a quote!

Basic information on data protection: In accordance with the GDPR and the LOPDGDD, FAIN ASCENSORES S.A. will process the provided data in order to contact you with the information you need. For more information about the processing of your data and to exercise your rights, please visit our privacy policy